|

|

|

|

|

|

|

|

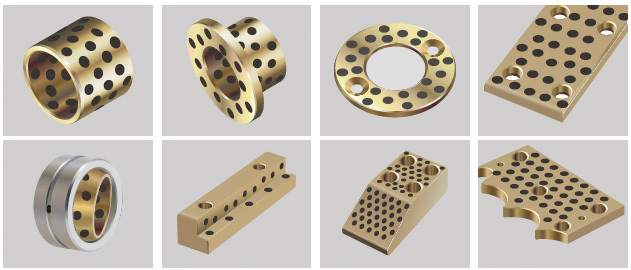

SOD slide plate, standard type, bronze SO#50SP2 with graphite

SOD slide plates consist of highly wear-resistance copper cast alloy whose sliding surfaces are evenly provided with a certain percentage of solid lubricant plugs according to work condition, high-strength copper alloy provides a high load-bearing capacity and the solid lubricant can be formation of low friction film.

Under technical dry running conditions, the bearing surface is designed with thick running-in film which

enables the solid lubricant to be transferred to the counter material at the first contact.

|

|

|

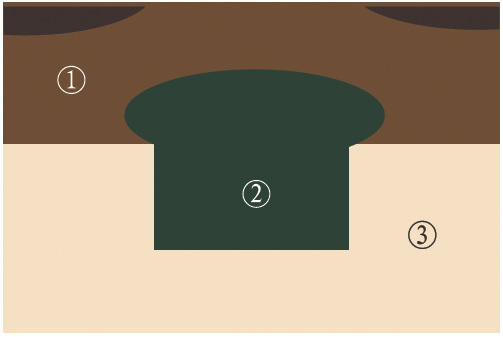

Structures

① Solid lubricant film

② Solid lubricant plug

③ Bronze backing |

|

Material Features

- Allows maintenance-free and long-life operation;

- Suitable for high static and dynamic loads;

- With low and smoothly coefficient of friction and without stick-slip effects;

- Suitable for dirty, corrosion, impact load and edge loading;

- The base material provided a good shock-absorbing capacity;

- Can be used over a large temperature range;

- Suitable for reciprocating, rotating and oscillating movement with start frequency

and difficulty to form oil film occasions;

- With low wear rate and long life service.

|

|

How It Works ?

When the mutual friction occurs between two non-lubricated surfaces, the two contacts with the uneven surface of the peak by the shear, stick-slip

and plastic deformation giving rise to friction and wear. Conventional lubricants can significantly reduce these effects, however, the conventional

lubricant will be more and more squeezed out of the contact area with increasing surface which formed the dry friction or boundary lubrication.

With SOD slide plates, the lubrication is effected by the sliding material itself, The solid lubricant is released from the friction

material by micro-movement. This gives the sliding partners smooth surfaces with a firmly adhesive solid lubricant film, the solid lubricant film

remains within the contact area even under heavy loads. The embedded solid lubricant plugs can be continuously provided to the friction surface

to reduce friction resistance and wear, thus make the bearing can be worked under low wear rate and long-life service.

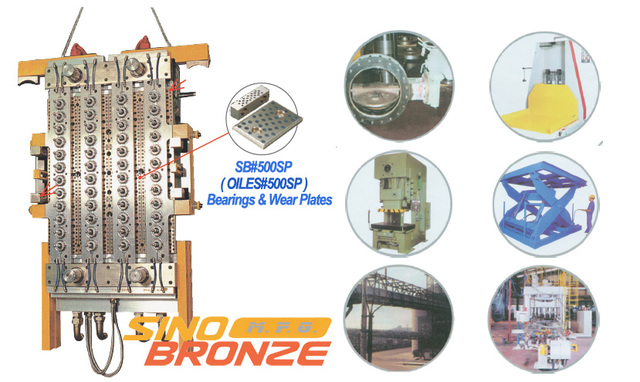

Typical Applications

The product is widely used in

- continuous casting rolling machine

- mining machinery

- shipping machinery

- turbine

- injection machinery

- auto mould and so on...

|

|

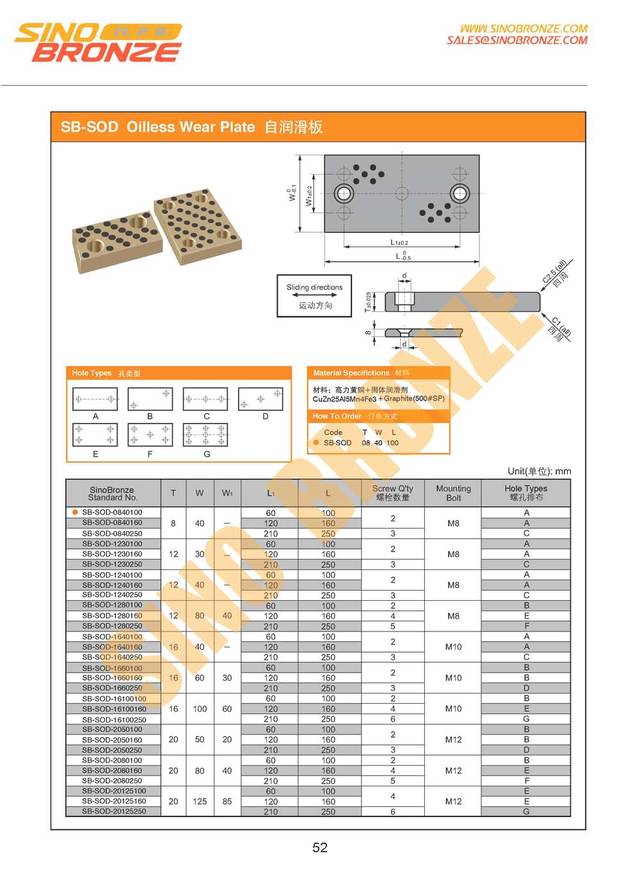

SOD slide plate, standard type, bronze SO#50SP2 with graphite --- Metric Size

|

SOD-301, SOD-302, SOD-303, SOD-304, SOD-305, SOD-306, SOD-307, SOD-308, SOD-309, SOD-310, SOD-311, SOD-312, SOD-313, SOD-314, SOD-315, SOD-316, SOD-317, SOD-318, SOD-319, SOD-320, SOD-321, SOD-322, SOD-323, SOD-324, SOD-325, SOD-326, SOD-327, SOD-328, SOD-329, SOD-330,

SOD-0840100, SOD-0840160, SOD-0840250, SOD-1230100, SOD-1230160, SOD-1230250, SOD-1240100, SOD-1240160, SOD-1240250, SOD-1280100, SOD-1280160, SOD-1280250, SOD-1640100, SOD-1640160, SOD-1640250, SOD-1660100, SOD-1660160, SOD-1660250, SOD-16100100, SOD-16100160, SOD-16100250, SOD-2050100, SOD-2050160, SOD-2050250, SOD-2080100, SOD-2080160, SOD-2080250, SOD-20125100, SOD-20125160, SOD-20125250