|

|

|

|

|

|

|

|

SB-GT-GE | spherical plain bearings

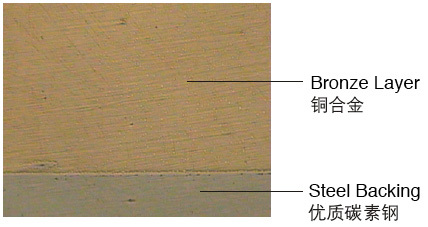

SB-GT marterial is steel shell with cast bronze bearing material liner with specially formulated solid lubricants

embedded into the holes in the liner material. The process of casting bronze on steel achieves an integral

metallurgical structure between bronze and steel with an increased carrying capacity while the material cost

is considerably reduced. The solid lubricant can reduce the coefficient of friction and performs the

self-lubricating function.

|

|

|

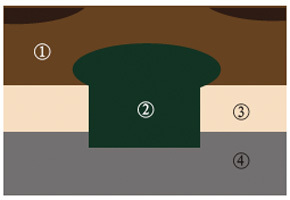

Structures

① Solid lubricant film

② Solid lubricant plug

③ Bronze layer

④ Steel backing |

|

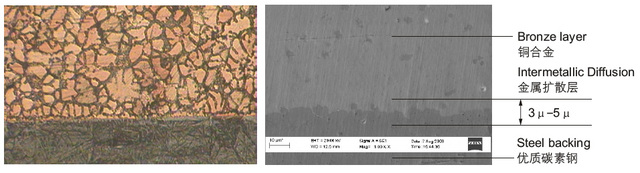

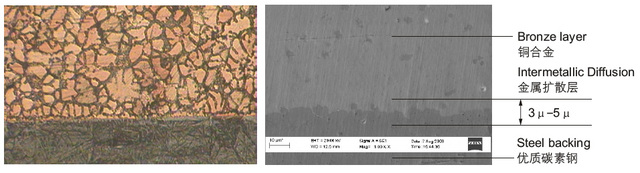

Material Features

The microstructure of the steel and bronze interface shows there have intermetallic diffusion between 3u to 5u during the casting

process. This ensures perfect adhesion and in every case, the mechanical properties of the interface are superior to those of

bronze itself.

This intermetallic diffusion offers excellent mechanical properties and with partial transfer of load to the steel. The thin bronze

layers allows the material have closed thermal expansion thus is accept the final production have heating process in case of, that

means SB-GT material can keep the accurate and constant mechanical clearance.

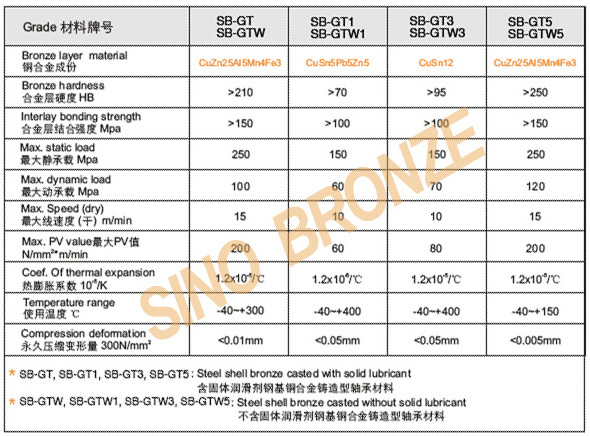

Material Types

Typical Application

SB-GT material parts can be widely used under high temperature and high load with low speed conditions, such as successive casting

machinery, mineral machinery, injection molding machinery, dock machinery, and so on…

Other Standard SB-GT Bearings

|

Non-Standard SB-GT Bearings