|

Composition Analysis of SB-48 ( CuPb30, SAE-48, JIS-KJ3 Bronze Alloy )

• Technical Data

Typical Applications

The main applications are in Automotive and Industrial products. Other Standard Wrapped Bimetal Bushing Shapes

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Gallary of Bimetal Bearings / Bimetallic Bushings / Bimetal Leaf Spring Bushings | |||

|

|||

| SAE-792 (CuPb10Sn10) Bimetal Bushings | |||

|

|

|

|

| Babbitt Bearings ( SAE783 / AlSn20Cu ) | Bimetal Bush ( SAE792 / CuPb10Sn10 ) | Bimetal Bush | X groove | 50x55x60 mm | Bimetal Bush (SAE799) with Oil Prockets |

|

|

|

|

| Combined Bush - bronze on steel | Centrifugal Cast Bronze on Steel Bush | Oil grooved Bimetal Bushing | Bimetallic Bearing with Oil Groove |

|

|

|

|

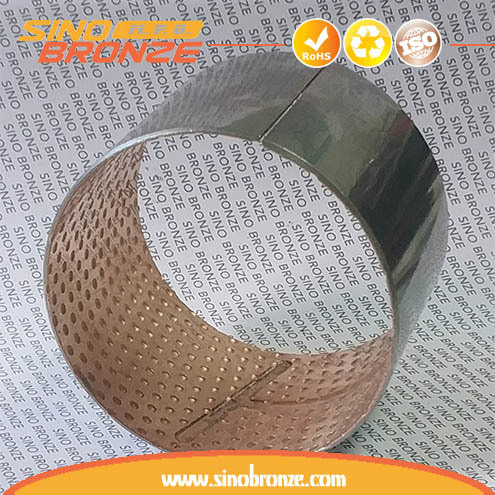

| Bimetal bearing with oil pockets | Bimetal bush with oil grooves | Bimetal bush with diamond graphites | Wrapped Bimetal Bush |

|

|||

| SAE-799 (CuPb24Sn4) Bimetal Bushings | |||

|

|

|

|

| Bimetallic bushing with diamond oil Pockets | Oil grooved bimetal bushing | BS PB1 (CuSn10) Bimetal Bushing | DIN17670 CuPb6Sn6Zn3 Bimetal Bushing |

|

|

|

|

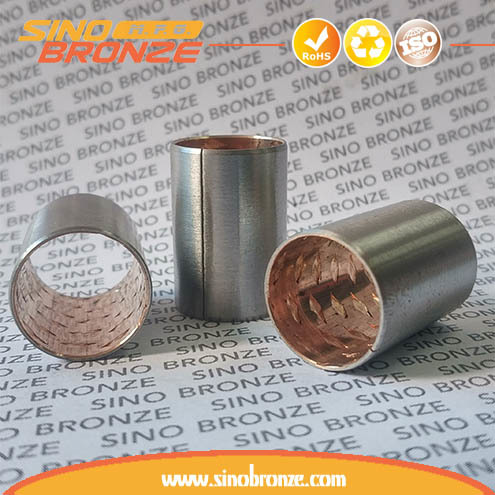

| CuSn6 (2.1020) Bimetal Bushing | CuSn6.5P Bimetal Bushing | CuPb10Sn10 Bimetal Bushing | SAE792 Bimetal Busing |

|

|

|

|

| SAE799 Bimetal Bushing | DIN17670 Bimetal Bushing | CuPb24Sn4 Bimetal Bushing | CuPb6Sn6Zn3 Bimetal Bushing |

|

|||

| BS PB1 (CuSn10) Bimetal Bearings | |||

|

|

|

|

| BS PB1 Bimetal Bearing with spirial oil grooves inside |

CuSn10 Bimetal Bearing filled with graphites |

CuSn12 Bimetal Bearing with inside oil pockets |

CuSn12 Bimetal Bushing with oil inside oil groove and oil pockets |

|

|

|

|

| CuSn6 (2.1020) Bimetal Bearing | CuSn6.5P Bimetal Bearing | JIS-LBC3 Bimetal Bearing | JIS-LBC6 Bimetal Bearing |

|

|

|

|

| SAE-783 (AlSn20Cu) Bimetal Bushing | Customized BImetal Bushing with Taperd Bore | Standard Bimetal Bushing with SAE792 Slide Layer | Standard Bimetal Bushing with SAE-792 Slide Layer |

|

|||

| SAE-783 (AlSn20Cu) Bimetal Bushings / Babbitt Bearings | |||

|

|

|

|

| SAE783 Bimetal Bearings | SAE-783 Bimetal Bearings | AlSn20Cu Bimetal Bearings | SAE-48 (CuPb30) Bimetal Bearings |

|

|

|

|

| SAE-792 Bimetal Bearings with inside oil groove |

SAE-48 Bimetal Bearings with X-shaped oil groove inside |

CuPb30 Bimetal Bearings with oil pockets inside |

CuPb30 Bimetal Bearings with diamond-shaped graphite inside |

|

|

|

|

| CuSn8Ni1 Bimetal Bush with oil grooves aside the split |

Split Bimetal Bush with CuSn6AgFe3P Slide Layer |

CuPb10Sn10 Bush with inside grooves and Butt Jionts |

SAE792 Bush with inside grooves and Butt Jionts |

|

|||

| CuPb24Sn1 Bimetal Bush / CuPb24Sn1 Bimetal Bearing | |||

|

|

|

|

| Bimetal Bush sintered with CuPb7Sn7Zn3 Bronze Layer |

Bimetal Washer sintered with CuPb3Sn6Zn6 Slide Layer |

SAE783 Bimetal Bushing and SAE783 Bimetal Bearing Shell |

Vavious Sizes of SAE792 Bimetal Bushings with Copper-Plating |