|

|

|

|

|

|

|

|

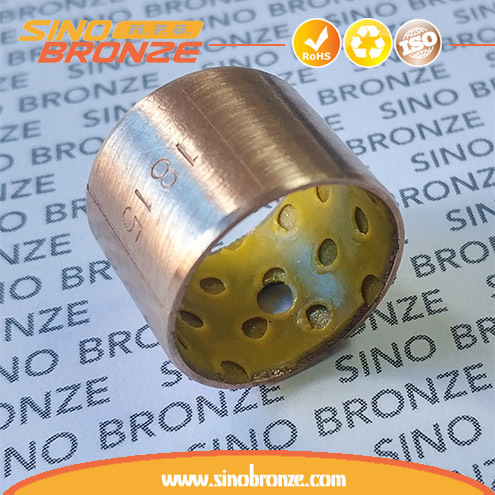

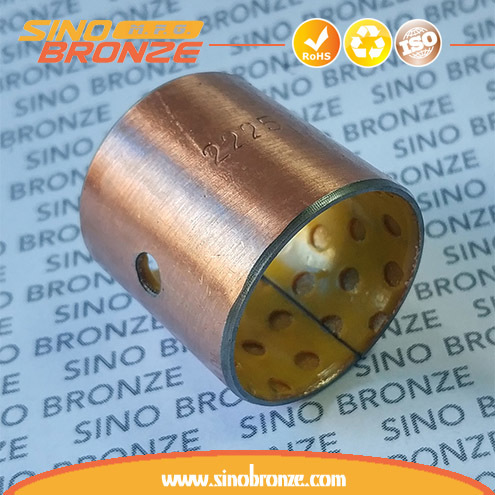

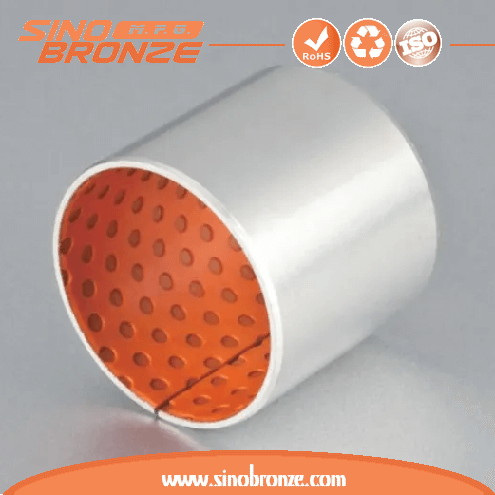

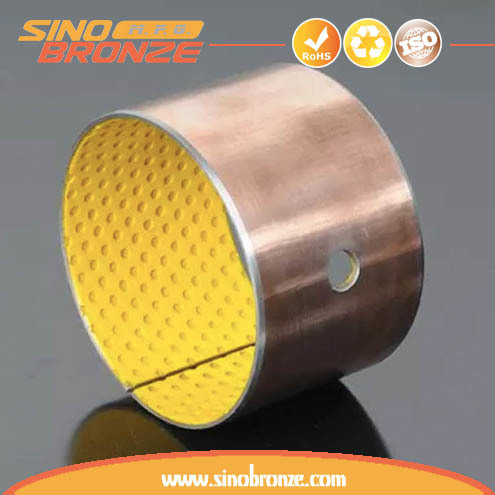

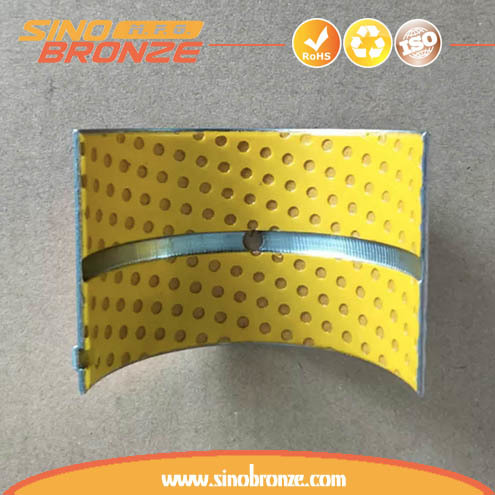

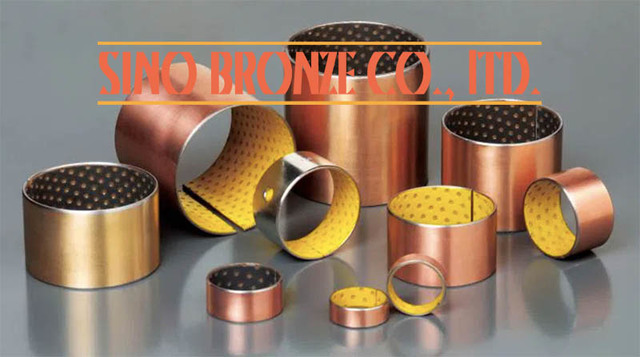

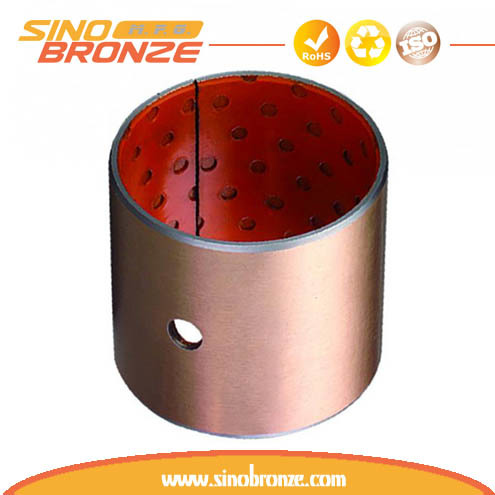

SB-DX bearing, bronze and POM lined, marginally lubricated, ISO3547, metric and inch size

Sintered POM and Bronze Powder on Steel Backing

POM + SIntered Bronze Powder + Steel Backing + Copper / Ting-plating

Features

Sinobronze DX bearings are suitable for rotating and oscillating movement, less maintenance requirements due to the long re-lubrication intervals, lower wear, lower susceptibility to edge loading, no absorption of water and therefore no swelling, good damping behaviours, good resistance to shock loads.

|

|

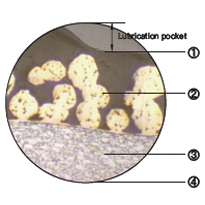

Structures

1.POM with MoS2 thickness 0.30~0.50 mm, it provides high wear resistance and low friction even with only minute volume of lubricant are supplied, this bearing surface carries a pattern of circular indents which should be filled with grease on assembly of the bearing.

2. Sintered bronze powder thickness 0.20-0.35mm, provides max. thermal conductivity away from the bearing surface, also serves as a reservoir for the resin mixture.

3. Low-carbon steel, provides exceptionally high load carrying capacity, excellent heat dissipation.

4. Copper/Tin plating thickness 0.002mm, provides good corrosion resistance.

|

|

Technical Data of SB-DX materials

| Data |

Types |

SB- DX

|

DX -SB1

|

DX -SB2 |

DX -SB3 |

SB- HIEX |

|

With Lead

or Without Lead

|

No oil pockets

& Without Lead

|

Bronze Backing

& Without Lead |

Blue Lining

& Without Lead |

High Temperature

& Without Lead |

| Materiai |

Steel + Bronze + POM (+Pb) + MSo2 |

Steel+ Bronze + POM + MSo2 |

Bronze + Bronze + POM + MSo2 |

Steel+ Bronze + POM + MSo2 |

Steel + Bronze + (PTFE+PEEK) |

Typicai

application |

It's used in many places of Vehicle/Automotive, Building equipment, Agricultural equipment,

Machine tooling building industry, forming machine tools, steel metallurgical machinery, mineral mountain machinery,

hydraulic industry and rolling steel industry, etc. |

High temperature condition like high-pressure gear pump, water injection pump, hydraulic motor and spray painting food processing. |

| Max. Loading P |

Static load

N/mm² |

250 |

250 |

250 |

250 |

250 |

| Very low speed N/mm² |

140 |

140 |

140 |

140 |

140 |

| Dynamic load N/mm² |

70 |

70 |

70 |

70 |

70 |

| Max.Speed Vm/s |

Grease

Lubrication |

2.5 |

2.5 |

2.5 |

2.5 |

2.5 |

| Max.PV limit |

3 |

3 |

3 |

3 |

3.6 |

| Friction coef u |

0.05~0.20 |

0.05~0.20 |

0.05~0.20 |

0.05~0.20 |

0.03~0.20 |

| Mating Axis |

Hardness (HB) |

>270 |

>270 |

>270 |

>270 |

>270 |

| Roughness (Ra) |

0.4~1.25 |

0.4~1.25 |

0.4~1.25 |

0.4~1.25 |

0.4~1.25 |

| Temperature Range ( ℃) |

-40~+120 |

-40~+120 |

-40~+120 |

-40~+120 |

-150~+250 |

| Thermal conductivity (W/mk﹣¹) |

50 |

50 |

65 |

50 |

50 |

| Coefficient of linear expansion |

11×10-6K |

11×10-6K |

11×10-6K |

11×10-6K |

11×10-6K |

| Outside Surface Plating |

copper/tin |

copper/tin |

No copper/tin |

copper/tin |

copper/tin |

| * Initial pre-lubrication at assembly is strongly recommended. |

|

|

Typical Applications

Recommended for applications involving intermittent operation or boundary lubrication...

Automotive: suspension joints, kingpin assemblies and stub axles of tucks, automobile driving joint hinges, steering and other linkages, articulation joints, rear chassis hinges, fair leader rollers...

Machine tool building industry: spindles in drill, grinding, and milling machines, ram guide plates in multi-ram presses...

Agricultural equipment: gearbox, clutch, bale trips and wheel caster swivels for bale accumulators, front axle pivot bearings, steering idler box bearings and kingpin bearings for harvesters... It is especially well-suited for applications where lubricant can not be supplied continuously or repeatedly.

|

|

Other Standard DX Shapes

|