|

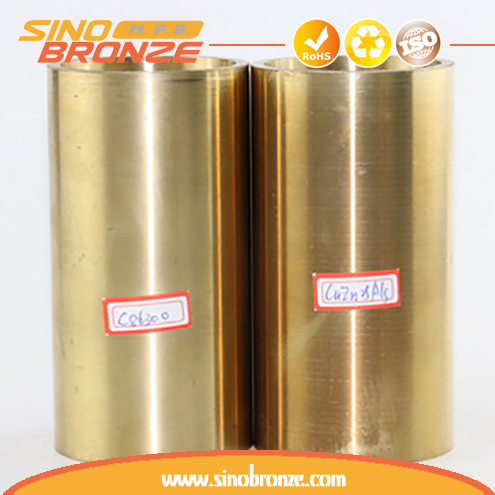

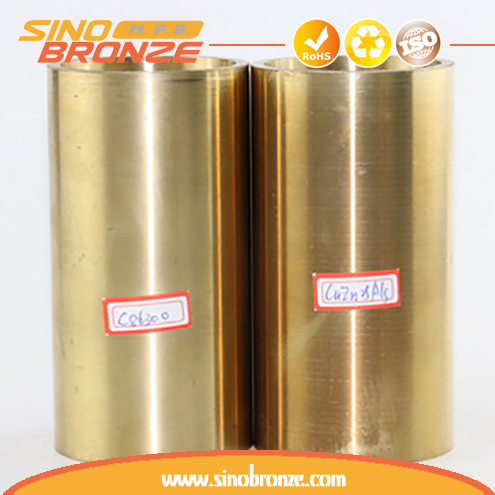

| • SINOBRONZE with C86300 MANGANESE BRONZE |

| |

|

C86300 (CuZn25Al6Fe3Mn3, CuZn25Al5, CC762S) is known for its high strength and hardness, use of manganese as an alloying agent, and high levels of zinc. Besides its excellent mechanical qualities, C86300 also has good corrosion resistance.

SINO BRONZE CO., LTD. uses C86300 (CuZn25Al6Fe3Mn3, CuZn25Al5, CC762S) for high load, lowspeed applications including Industrial Bearings, Gears, Valve Stems, Bushings, Cams, Wear Rings for Pressing Dies for Wood Pulp Industry, HighStrength Machine Parts, Hooks, Frames, Shafts, Marine ...etc.

|

| • Chemical Composition C86300 MANGANESE BRONZE |

|

Cu

|

Sn

|

Pb

|

Zn

|

Fe

|

Ni

|

Sb

|

P

|

S

|

Al

|

Mn

|

Si

|

|

60.00-66.00

|

0.2

|

0.2

|

22.00-28.00

|

2.00-4.00

|

1.0A

|

N/A

|

N/A

|

N/A

|

5.00-7.50

|

2.50-5.00

|

N/A

|

|

| • Mechanical Properties C86300 MANGANESE BRONZE |

|

Tensile Strength

(min)

|

Yield Strength

(at .5% extention under load min)

|

Elongation

(in 2in. or 50mm min, %)

|

Brinell Hardness

(min)

|

Remarks

|

|

Ksi

|

MPa

|

Ksi

|

MPa

|

- |

- |

- |

|

110

|

758

|

62

|

427

|

14

|

210

|

- |

|

| • Typical Applications C86300 MANGANESE BRONZE |

| |

|

|

|

|

|

|

| • Industrial Bearings |

|

• Wear Plates |

|

• Bridge Pins |

|

• Bridge Pins |

| • Liners |

|

• Gibs and Ways |

|

• Worm Gears |

|

• Adjusting Nuts |

| • Forming Dies |

|

• Wear Rings |

|

• Pump Rods |

|

• Sleeve Bearings |

| • Valve Seats |

|

• Guide Pin Bushings |

|

|

|

|

|

|

|

|

|

|

|

|

|

C86300, CuZn25Al5,

Bronze Bearing |

|

86300, CuZn25Al5,

Bronze Bushing |

|

CuZn25Al6Fe3Mn3

Bronze Bushing |

|

SAE430B

Bronze Bearing |

|

|