|

|

|

|

|

Iron Materials

|

Basic Materials

|

Chemical Composition (%)

|

Other Materials

|

|

SAE863 Type3

SATM B439-70 GR4

Mil-B-5687C TypeⅡCompB

|

Cu: 18.0~22.0,

Fe: Rest

Particles: 2.0

|

MPIF: F - 0000 - K23 / ASTM: B 439 - 83 / DIN: SINT - B00

MPIF: F - 0008 - K32 / ASTM: B 439 - 83 / DIN: SINT - B11

MPIF: FG - 0303 - K16

MPIF: F - 0000 - K15 / K23

MPIF: F - 0005-K20 / F - 0005-K28

MPIF: F - 0008 - K20 /F - 0008 - K32

|

Bronze Alloy List

Typical Applications

Diesel blinds bushings, Agricultural Machinery combine harvester, tractors , Sewing Machine , Coal Coal Conveyor , Tape Recorder,

Movie Projector, Automotive front suspension rods and other components, Horizontal Conveyor rolling mill, plate mill finishing sector,

oil resistant rubber, reaming mill for the electric trains drive braking, saw frame joints , and other applications.

SB-SIG Bearing Features

The main factors affecting their physical mechanical properties and friction performance are the graphite content, porosity and material's microstructure.

1) Graphite Content

Mixing the graphite powder and iron powder, when compacting it to different shape, the graphite have the effect of lubricating in favor of compact

density distribution. After adding the graphite into the iron materials, it can reduce friction and wear, increasing the allowed sliding speed and load,

and the products tensile strength enhancing acording to the graphite content increased. With 3% graphite content, the Sintered Fe-C

self-lubricating bearings with the best friction performance.

2) Porosity

The porosity is another important feature for Sintered Fe-C selflubricating bearings. It have great affection for the materials friction performance

of Sintered Fe-C selflubricating bearings. It is exactly with the same relationship between the binding of the limit load and porosity, and the

concerning between the friction/wear and the material' s porosity of Sintered Fe-C selflubricating bearings.

A large number of small gaps in the materials structure not only ensure to form oil fim at the bearing work surface, also guarantee the normal

work in the condition of additional oilless from outside under a cetain time and some conditions.

3) Structure

The mechanical properties and friction performance of Sintered Fe-C selflubricating bearings mainly depends on the the materials structure.

Materials carbon content determines its structure is pearlite, pearlite ferrite or pearlite cementite. In the materials of Sintered Fe-C

self-lubricating bearings, the pearlite content significantly affect the properties of their friction:

- With 60~70% pearlite content, sliding speed with the least affection to the friction coefficient;

- Pearlite content less than 60%, friction coefficient increasing with sliding velocity increased accordingly;

- Pearlite content more than 70%, friction coefficient reducing with sliding velocity increased accordingly.

- Sintered Fe-C selflubricating bearing materials with 0.8~1% graphite content, it will be the most stable for the physical mechanical

properties, processing performance and structure.

SB-SIG Bearing Advantages

1. Dry working condition, provides maintenance free operation

2. High thermal stability

3. Can be applied in widely temperatue

4. With lower wear rate and long life service

5. Metal based materials is electrically conductive and shows no electrostatic effects

6. High static load and dynamic load capacity

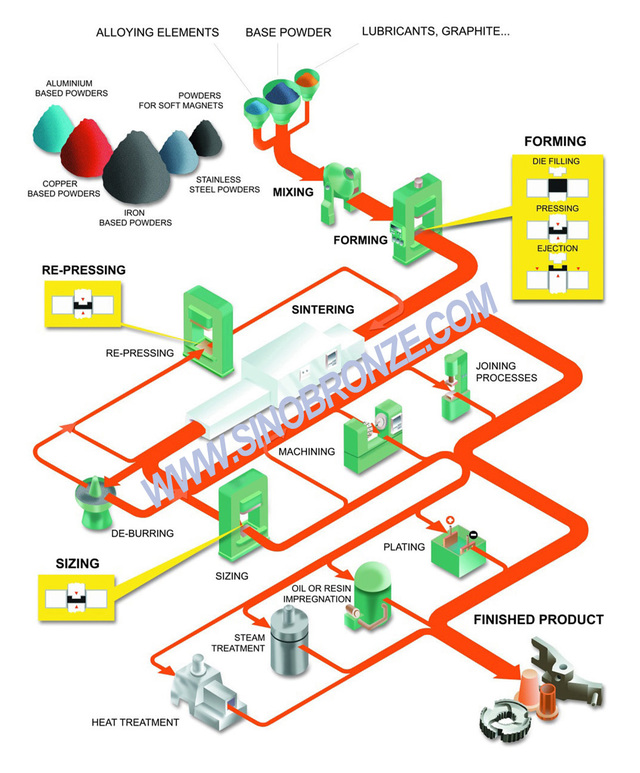

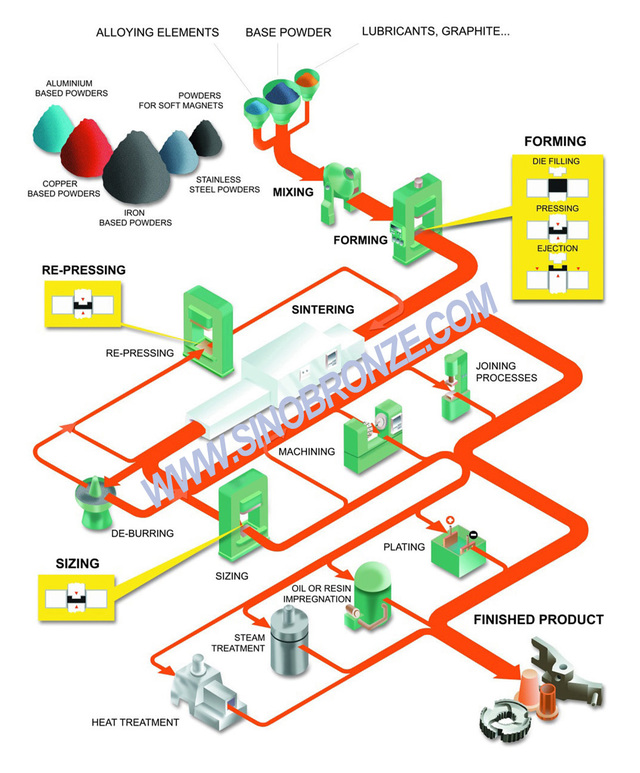

Sinobronze's Powder Matallury Process

Other Standard Sintered Parts with Oil-impregnated

|