|

|

|

|

|

|

|

SB-SBG | sintered bronze parts with graphites / MoS2 (oil-impregnated)

When adsorption molecular lubrication in the condition of high speed or high pressure, oil temperature rise due to friction heat, the arrangement of adsorbed molecular disordered and to final resolve.

The extreme pressure used in SINOBRONZE products including phosphorus, sulfur and other oil soluble

organic compounds, and also including organic metal compounds like Zn, Pb, Sb etc. Their role is due to

the chemical reaction between the friction heat additive and metal martix, to form the protective film on

the base metal furnace, and to prevent adhesion between the metal under high pressure.

|

Bronze Materials

|

Basic Materials

|

Chemical Composition (%)

|

Other Materials

|

|

SAE841

ASTM B438-70 GR1 Type Ⅱ

DIN30910 PART3

SINT A50 Mil-B-5687C

TypeⅠCompA

|

Cu: 87.5~90.5,

Fe: 1.0max,

Sn:9.5~10.5,

P:1.75,

Praticles:0.5

|

MPIF: CT- 1000 - K19 / ASTM: B 438 - 83a

MPIF: CT - 1000 - K26 / ASTM: B 438 - 83a / DIN: SINT - A50

MPIF: CT - 1000 - K37 / ASTM: B 438 - 83a / DIN: SINT - B50

MPIF: CT - 1001 - K23 / ASTM: B 438 - 83a / DIN: SINT - B51

MPIF: CT - 1001 - K33 / ASTM: B 438 - 83a / DIN: SINT - C51

MPIF: CTG - 1004 - K10

MPIF: CTG - 1004 - K15

|

Bronze Alloy List

Solid Lubricants

There are many types of solid lubrications, the Graphite and MoS2 is the most commonly used into SINOEBROZE' s products, with the following characteristics of this bearings:

1. Can work under high temperature and pressure;

2. Suitable for low speed sliding, can reduce the stick slip phenomenon and the "cold welding";

3. Applicable to a wide temperature range, such as under the temperature of liquid nitrogen and liquid oxygen,

it is still can maintain their lubricating properties;

4. Applicable to high altitude and strong solar radiation;

5. Do not react with the environmental media, solvents, fuels and combustion supporting agent, and can be

used in the environments of acid, alkali and seawater.

6. Can be used for non-sealed environment with dust;

7. Apply to prevent oil pollution of the occasion;

8. Simplify or cancel the unreliability of lubrication system ;

9. Applicable to the environment of the oil erosion loss easily.

Typical Applications

Food Processing, Electrical Equipment, Pharmaceutical equipment , Stove and oven, Aerospace, Vacuum Technology,

Glass Manufacturing Industry.

SB-SBG Bearing Advantages

1. Dry working condition, provides maintenance free operation

2. High static load and dynamic load capacity

3. High thermal stability

4. Can be applied in widely temperature

5. Suitable for radioactive environments

6. Metal based materials is electrically conductive and shows no electrostatic effects

7. Can applied in dirty and corrosion environment

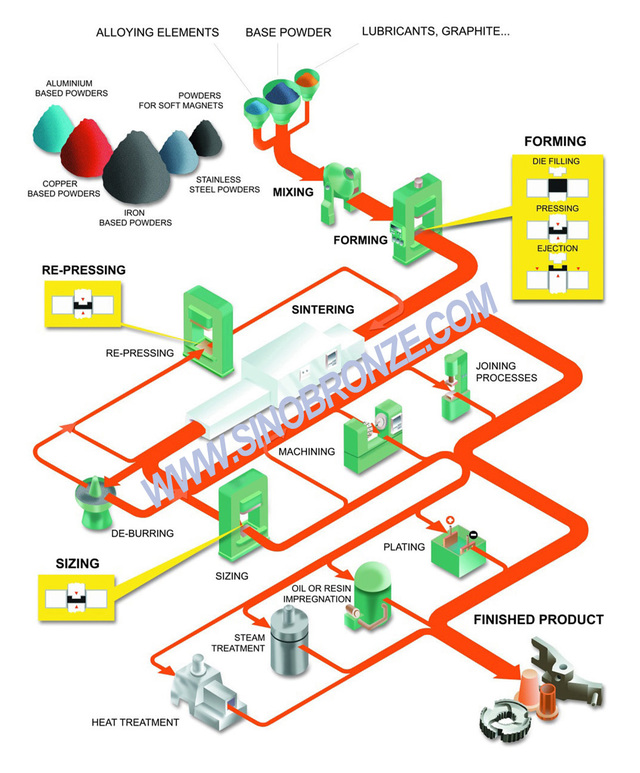

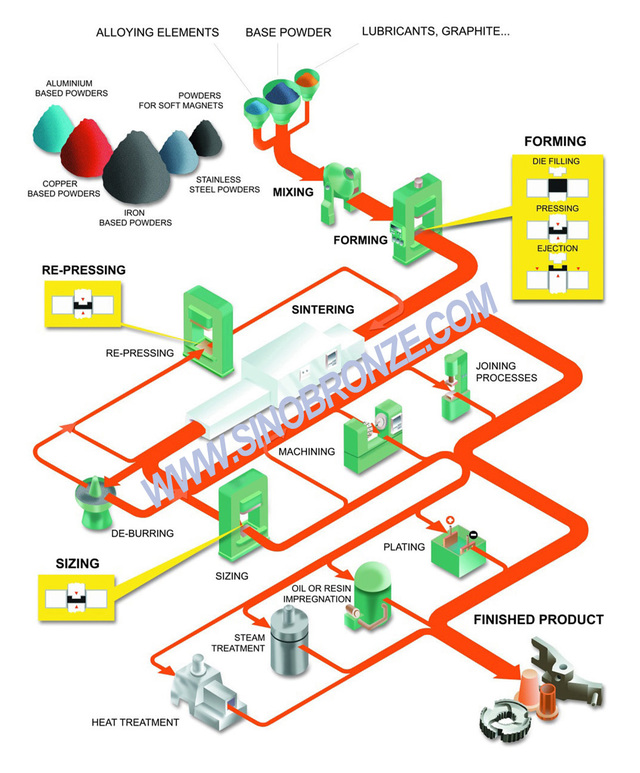

Sinobronze's Powder Matallury Process

Other Standard Sintered Parts with Oil-impregnated

|