|

Other Standard SB-HIEX Shapes

|

| Gallery of SB- HIEX Bearings, SB- HIEX Bushings, SB- HIEX Washers, SB- HIEX Bearing Shells, SB- HIEX Plates & SB- HIEX Strips |

|||

|

|||

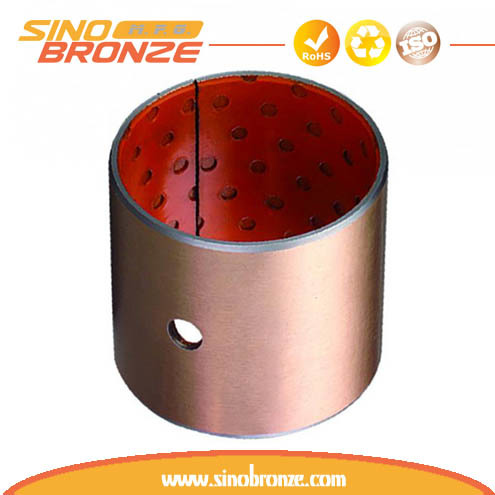

| DX Bearings & HX Bearings | |||

|

|

|

|

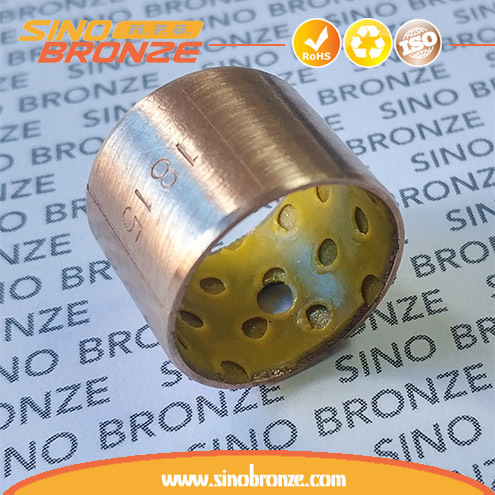

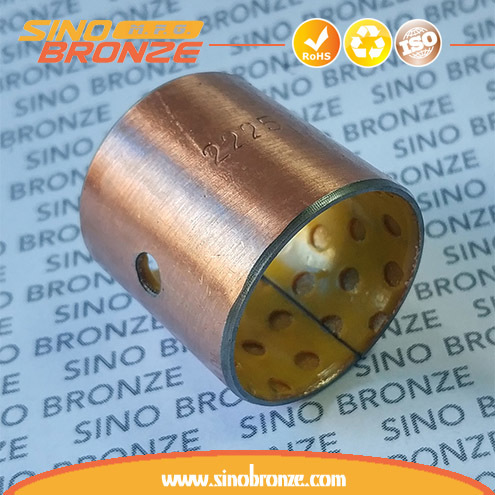

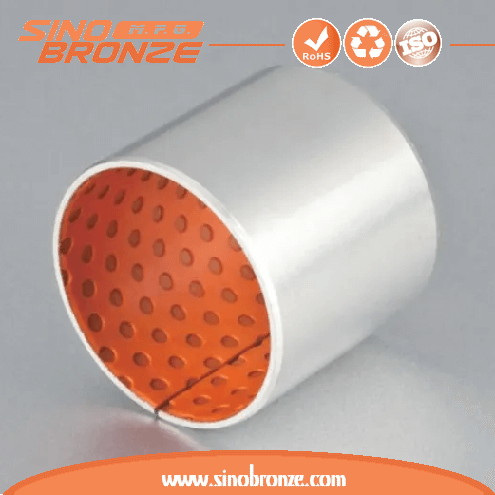

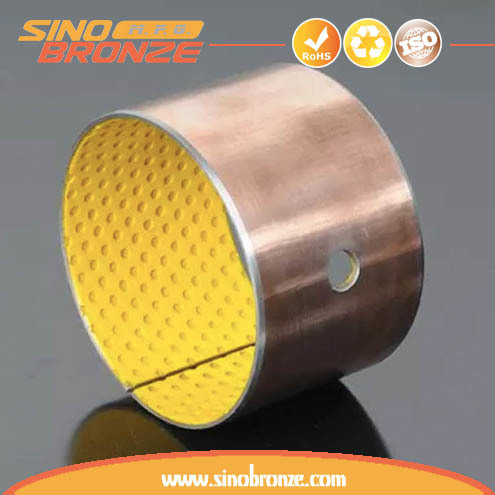

| DX bearing 1815DX | DX bearing 2225DX | DX bearing 5550DX | DX bearing 9060DX |

|

|||

| POM coated DX slide bushings | |||

|

|

|

|

| DX bushing 4550DX | DX bushing 215200DX | DX bushing 2525DX | DX bushing 2525DX |

|

|||

| DX bushings with tin-plating or copper-plating | |||

|

|

|

|

| POM lined DX bushing | POM lined DX bushing | POM lined DX bushing | POM lined DX bushing |

|

|||

| POM sintered layer / DX bearings and DX bushings | |||

|

|

|

|

| POM lined DX bearing | POM lined DX bearing | POM lined DX bearing | POM lined DX bearing |

|

|||

| Customized DX bearings, DX bushings, DX washers with various oil grooves | |||

|

|

|

|

| POM coated DX bearing | POM coated DX bearing | POM coated DX bearing | POM coated DX bearing |

|

|||

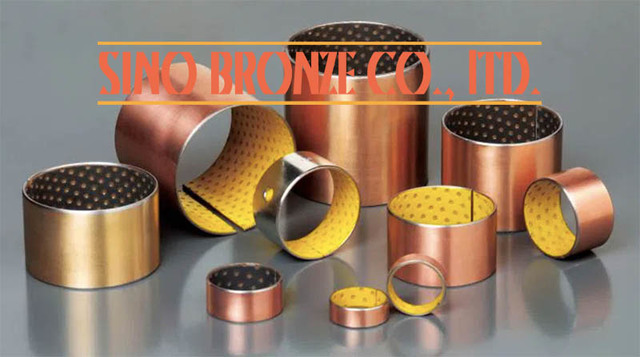

| SB- HIEX slide bushings / SB- HIEX self lubricating bearings / SB- HIEX oilless bearings | |||

|

|

|

|

| POM coated DX bushing | POM coated DX thrust washer | POM coated DX bushing | POM coated DX bushing |

|

|||

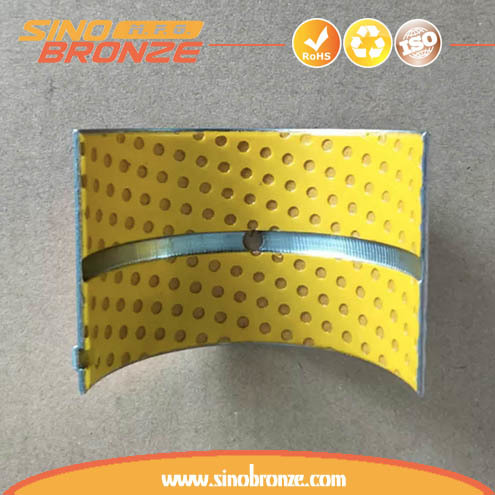

| DX bearing shell / DX bearing shell sets / POM coated bearing shell set | |||

|

|

|

|

| POM coated bearing shell with oil hole and oil groove |

POM coated bushing shell with oil hole and oil groove |

POM coated bearing shell set with oil hole and oil groove |

POM coated bushing shell set with oil hole and oil groove |

|

|||

| Slide bearings coated with PEEK and PTFE, SB- HIEX bearings and SB- HIEX Washers | |||

|

|

|

|

| POM sintered DX bushing | POM sintered DX bearing and POM sintered DX washer |

PEEK sintered HIEX bushing | POM sintered DX bearing |

|

|||

| POM coated slide bearings and POM coated slide plates | |||

|

|||

| PEEK and PTFE coated slide bearings and PEEK coated slide plates (SB- HIEX) | |||

|

|||

| SB- DX bearings & SB- HI-EX bearings | |||

S10150HX S15190HX S20190HX S25190HX