DUB bush, PTFE lined, BRONZE backing, self lubricating dry bearings

|

|

|

|

|

|

DUB bush, PTFE lined, BRONZE backing, self lubricating dry bearings

Sintered PTFE and Bronze on Bronze Backing (Maintenance-free Material)

PTFE / Fibre + Bronze + Bronze Backing

Features

Suitable for dry running, low coefficient of friction, lower wear, good sliding characteristics, the transfer film created can protect the mating metal surface, suitable for rotary and oscillating movement. Very high chemical resistance, low absorption of water and swelling, also performs very good lubrication feature, the bronze backing provides the improved corrosion resistance comparing with SBU bearings.

|

|

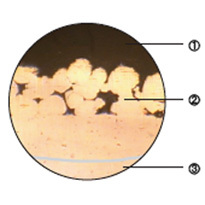

Structures

1. PTFE/fibre mixture thickness 0.01~0.03mm, provides an excellent initial transfer film, which effectively coats the mating surfaces of the bearing assembly, forming an oxide type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides max. thermal conductivity away from the bearing surface, also serves as a reservoir for the PTFE/Fibre mixture.

3. Bronze backing, provides exceptionally high load carrying capacity, excellent heat dissipation and very good corrosion resistance.

|

|

Typical Applications

This material meets the demanding criteria for long life and trouble-free performance with or without lubricant, of high safety factor even.

The bronze backing provides a high corrosion resistance, anti magnetic properties and a good thermal conductivity, The bearings are particularly appropriate for high temperature environment where no oil is efficient and the machine must be under successive long period working condition.

The typical applications covered Steel metallurgy industry such as bushes for roller grooves of successive casting machines, cement grouting pumps and screw conveyers for cement and so on.

Technical Data

|

Physical and Mechanical Properties

|

Usage

|

|

Thermal Conductivity λ

|

60

|

W/mK

|

dry

|

very good

|

|

Maximum Operating Temperature Tmax

|

280

|

°C

|

oil lubricated

|

good

|

|

Minimum Operating Temperature Tmin

|

-200

|

°C

|

grease lubricated

|

fair

|

|

Compressive Yield Strength σc

|

300

|

N/mm2

|

water lubricated

|

good

|

|

Maximum Static Load Psta,max

|

140

|

N/mm2

|

process fluid lubricated

|

fair

|

|

Maximum Dynamic Load Pdyn,max

|

140

|

N/mm2

|

|

|

Maximum Sliding Speed V-dry

|

2.5

|

m/s

|

|

Maximum PV Factor-dry, continuous operation

|

1.8

|

N/mm2 * m/s

|

|

Maximum PV Factor-dry, intermittent operation

|

3.5

|

N/mm2 * m/s

|

|

Coefficient of friction f-dry

|

0.02-0.25

|

|

|

|

Coefficient of friction f-oil lubricated

|

0.02-0.12

|

|

|

DUB standard cylindrical bushings

Other Standard DU-B Shapes

|

DU-B bearing & DUB bushing (SF-1B series)

|

|

|

|

|

|

|

| BB3540DUB |

|

4025DUB |

|

4530DUB |

|

5030DUB |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Gear Pump Bush |

|

BB5540DUB | 55x60x40 mm |

|

BB6570145.5DUB | 65x70x14.5 mm |

|

DU-B bearing | 25x28x30 mm |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| DU-B bush | 19.5x22.35x16 mm |

|

1212DUB | 12 x 14 x 12 mm |

|

DUB bearing | 22.35x25.55x31.75 mm |

|

1820DUB | 18x20x20 mm |

|

1215DUB 1220DUB 1225DUB 1310DUB 1320DUB 1405DUB 1410DUB 1412DUB 1415DUB 1420DUB 1425DUB 1510DUB 1512DUB 1515DUB 1520DUB 1525DUB 1610DUB 1612DUB 1615DUB 1620DUB 1625DUB 1720DUB 1810DUB 1815DUB 1820DUB 1825DUB 2010DUB 2015DUB 2020DUB 2025DUB 2030DUB 2215DUB 2220DUB 2225DUB 2230DUB 2415DUB 2420DUB 2425DUB 2430DUB 2515DUB 2520DUB 2525DUB 2530DUB 2550DUB 2815DUB 2820DUB 2825DUB 3010DUB 3015DUB 3020DUB 3025DUB 3030DUB 3040DUB 3220DUB 3230DUB 3240DUB 3520DUB 3530DUB 3535DUB 3540DUB 3550DUB 3720DUB 4020DUB 4030DUB 4040DUB 4050DUB 4520DUB 4530DUB 4540DUB 4545DUB 4550DUB 5020DUB 5030DUB 5040DUB 5050DUB 5060DUB 5520DUB 5525DUB 5530DUB 5540DUB 5550DUB 5555DUB 5560DUB 6020DUB 6030DUB 6040DUB 6050DUB 6060DUB 6070DUB 6530DUB 6550DUB 6570DUB 7040DUB 7070DUB 7560DUB 7580DUB 8040DUB 8060DUB 8080DUB 80100DUB 8530DUB 8560DUB 85100DUB 9060DUB 90100DUB 9560DUB 95100DUB 10050DUB 10060DUB 100115DUB

02DUB02 02DUB03 025DUB025 025DUB04 03DUB03 03DUB04 03DUB06 04DUB04 04DUB06 05DUB06 05DUB08 06DUB03 06DUB04 06DUB06 06DUB08 06DUB10 06DUB12 07DUB08 07DUB12 08DUB04 08DUB06 08DUB08 08DUB10 08DUB12 08DUB14 09DUB06 09DUB08 09DUB10 09DUB12 10DUB04 10DUB08 10DUB12 10DUB14 10DUB16 11DUB14 12DUB04 12DUB06 12DUB08 12DUB10 12DUB12 12DUB16 14DUB04 14DUB06 14DUB12 14DUB14 14DUB16 14DUB20 16DUB06 16DUB08 16DUB12 16DUB16 16DUB20 16DUB24 18DUB06 18DUB10 18DUB12 18DUB16 20DUB06 20DUB12 20DUB14 20DUB16 20DUB20 20DUB28 22DUB12 22DUB16 22DUB24 22DUB28 24DUB08 24DUB16 24DUB18 24DUB20 24DUB24 24DUB32 26DUB16 26DUB16 26DUB24 28DUB28 28DUB32 30DUB12 30DUB16 30DUB30 30DUB36 32DUB08 32DUB16 32DUB24 32DUB28 32DUB32 32DUB40 34DUB08 34DUB12 34DUB16 34DUB24 34DUB28 34DUB32 34DUB48 34DUB64 36DUB28 36DUB32 36DUB36 36DUB40 36DUB48 36DUB56 36DUB60 36DUB64 36DUB72 40DUB16 40DUB26 40DUB32 40DUB40 40DUB48 40DUB56 40DUB60 40DUB64 40DUB72 40DUB76 44DUB32 44DUB36 44DUB40 44DUB48 44DUB56 44DUB60 44DUB72 44DUB76 44DUB80 48DUB32 48DUB36 48DUB40 48DUB48 48DUB56 48DUB60 48DUB64 48DUB72 48DUB76 48DUB80 52DUB32 52DUB38 52DUB40 52DUB48 52DUB56 52DUB60 52DUB64 52DUB72 52DUB76 52DUB80 56DUB32 56DUB38 56DUB40 56DUB48 56DUB56 56DUB60 56DUB64 56DUB72 56DUB76 56DUB80 58DUB32 58DUB36 58DUB40 58DUB48 58DUB56 58DUB60 58DUB64 58DUB72