|

|

|

|

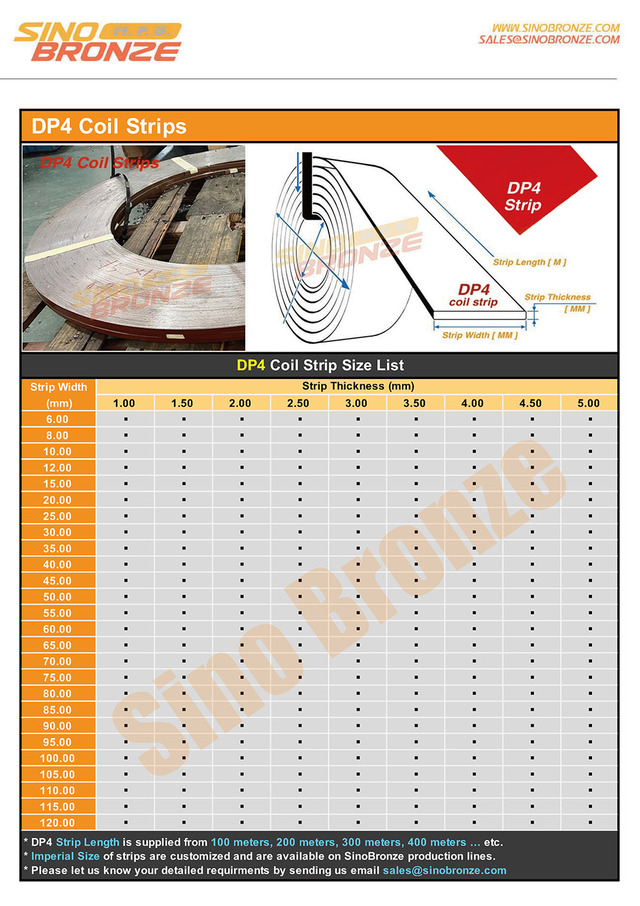

DP4 coil strips with Thickness 1.0/1.5/2.0/2.5/3.0/3.5/4.0 MM,

DIN1494 / ISO3547 standards |

|

Sintered PTFE and Bronze on Steel Backing, surface with copper-plating or tin-plating

PTFE / Fibre + Bronze + Steel + Copper plating / tin-plating

Features

Suitable for dry running with a low coefficient of friction, low wear rate, good sliding characteristics, the transfer film created will protect the mating metal surface.

Suitable for rotary and oscillating movement, high chemical resistance, lower absorption of water and reduced swelling. Also performs well with lubrication.

All our DU products are manufactured under DIN EN ISO 9001, ISO/TS 16949 and ISO 14001 approved quality management systems.

|

|

|

|

|

|

|

|

Structures

1. PTFE/Fibre mixture thickness 0.01~0.03mm, provides an excellent initial transfer film, which effectively coats the mating surfaces of the bearing assembly, forming an oxide type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides Max. thermal conductivity away from the bearing surface, also serves as a reservoir for the PTFE-Fibre mixture.

3. Low-carbon steel, gives exceptionally high load carrying capacity, excellent heat dissipation.

4. Copper/Tin plating thickness 0.002mm, provides good corrosion resistance.

|

|

Technical Data

|

Physical and Mechanical Properties

|

|

Usage

|

|

Thermal Conductivity λ

|

40

|

W/mK

|

dry

|

good

|

|

Maximum Operating Temperature Tmax

|

280

|

°C

|

oil lubricated

|

good

|

|

Minimum Operating Temperature Tmin

|

-200

|

°C

|

grease lubricated

|

fair

|

|

Compressive Yield Strength σc

|

350

|

N/mm2

|

water lubricated

|

fair

|

|

Maximum Static Load Psta,max

|

250

|

N/mm2

|

process fluid lubricated

|

fair

|

|

Maximum Dynamic Load Pdyn,max

|

140

|

N/mm2

|

|

|

Maximum Sliding Speed V-dry

|

2.5

|

m/s

|

|

Maximum PV Factor-dry, continuous operation

|

1.8

|

N/mm2 * m/s

|

|

Maximum PV Factor-dry, intermittent operation

|

3.5

|

N/mm2 * m/s

|

|

Coefficient of friction f-dry

|

0.02-0.25

|

-

|

|

Coefficient of friction f-oil lubricated

|

0.02-0.12

|

-

|

Typical Applications

This material meets the demanding criteria for long life and trouble-free performance with or without lubrication.

Automotive: tractors, combines, crop sprayers, earthmovers, graders and other construction, auto machines, specific uses in power steering cylinders, steering gear thrust washers, disc brakes, calipers and pistons, shock absorbers, governor linkage, windshield wiper motor, tilt gear assemblies...

Business machines: photocopy machines, typewriters, mail sorters, postage meter systems, computer terminal printers and peripheral equipment, automatic printing devices, mail processing machinery...

Hydraulics and valves: pumps including gear, rotary, water, axial piston, and other types, ball, butterfly, poppet steam, and other valves and valve trunnions...

Home appliances: tape recorders, refrigerators, air conditioners, cleaners, polishers, sewing machines, ovens, dishwashers, clothes washing machines...And materials handling, marine engine, packaging, textile equipment, tools...etc.

Coil Strip Sizes

Other Standard DP4 Shapes

|