|

|

|

|

|

|

|

|

DP4B flanged washer, fibres and PTFE lined, Bronze backing

Sintered PTFE and Polymer Fibres mixture and Bronze Powder on Bronze Backing

PTFE / Polymer Fibres + Bronze + Bronze Backing

Features

Suitable for dry running with a low coefficient of friction, low wear rate, good sliding characteristics, the transfer film reated will protect the mating metal surface. Suitable for rotary and oscillating movement, high chemical resistance, lower absorption of water and reduced swelling. Also performs well with lubrication.

|

|

Structures

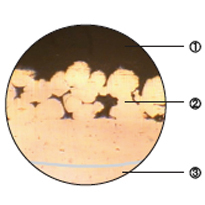

1. PTFE/Polymer fibres mixture thickness 0.01~0.03mm. Lead-free bearing layer provides an excellent

initial transfer film, which effectively coats the mating surfaces of the bearing assembly, forming an oxide type

solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides max. thermal conductivity away from the

bearing surface, also serves as a reservoir for the PTFE mixture.

3. Bronze backing, provides exceptional high load carrying capacity, excellent heat dissipation and very good

corrosion resistance.

|

|

Technical Data

Typical Applications

SBP4B is developed for high duty, oil lubricated, hydraulic applications...Automotive suspension struts, shock absorbers guide bushing,

hydraulic cylinders, gear pumps, motors, axial and radial piston pumps & motors.

SBP4B is designed mainly for using under lubricated conditions and it performs excellent wear resistance and low static/dynamic

friction coefficient.

Standard SBP4B Flanged Washer --- Metric Size

Other Standard SBP4B Bearing Shapes

|