|

SB-BM Materials & Technical Data SB-BM bearing surface Types for SB-BM bearings' Grooves and Indents Lock Types for SB-BM Bearinggs Typical Applications SB-BM has been widely used in water turbines, vane controls, injection moulding machinery, packing machines, construction equipment,

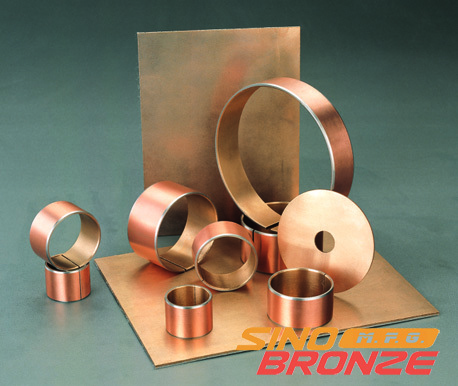

Other Standard Wrapped Bimetal Bushing Shapes    |

| • BM Parts We Made on Customer Requires | ||||||

|

|

|

|

|||

| BM Bushing | BM Bush Steel Backing + CuSn12 + Solid Graphites |

BM Bearing with oil grooves Steel Backing + CuSn10Pb + Solid Graphites |

BM Plates with oil grooves Bronze Backing + CuSn12 + Solid Graphites |

BM Slide Plates Steel Back + CuSn12 + Solid Graphites |

|||

|

|

|

|

|||

| BM Bearing | BM Bushing Steel Backing + CuSn12 + Solid Graphites |

BM Bush | BM Bushing Steel Backing + CuSn12 + Solid Graphites |

BM Bearing | BM Bush Steel Backing + CuSn12 + Solid Graphites |

BM Bearing | BM Bushing Steel Backing + CuSn10Pb10 + Solid Graphites |

|||

|

|

|

|

|||

| BM Bearing | BM Bushing Steel Backing + CuSn10Pb10 + Graphites |

BM cylincrical Bushing Steel Backing + CuSn10Pb10 + Graphites |

BM Plates with Graphite Plugs Stainless Steel + CuSn10Sn10 + Graphites |

BM Slide Plates Stainless Steel + CuSn10Pb10 + Graphites |

|||