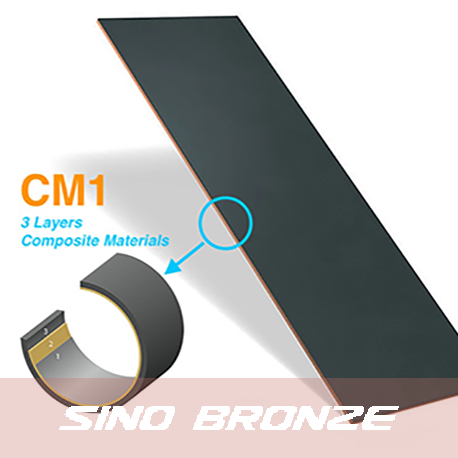

Plates & Strips with Three Layers' CM1 Composite Material, DIN1494 / ISO3547, Full Sizes

|

|

|

|

|

|

CM1 Composite Material Slide Plate, PTFE Lined, BRONZE Backing

Sintered PTFE and Bronze Powder on Bronze Backing (Maintenance-free Material)

PTFE / Fibre Layer + Bronze Layer + Bronze Backing

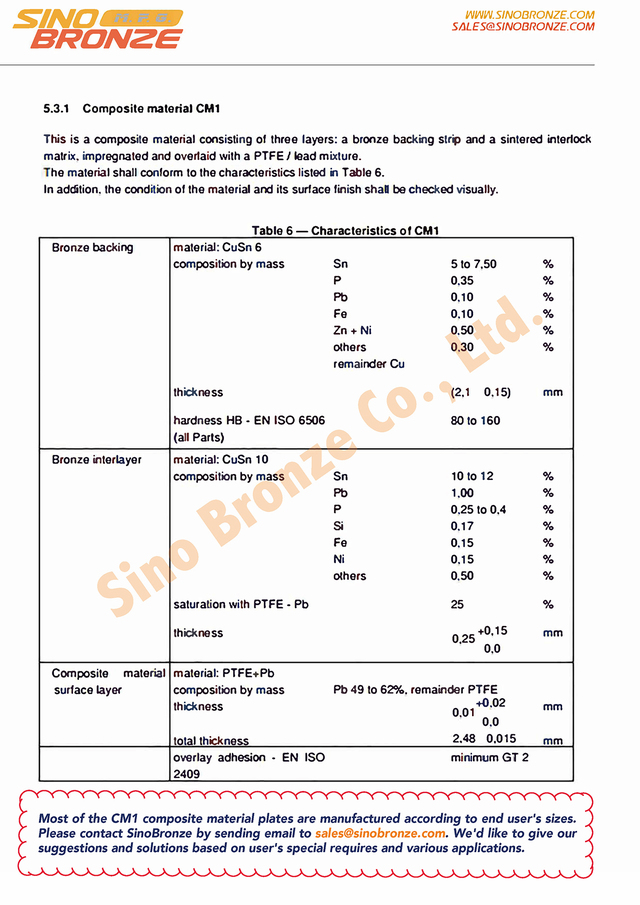

Composite material CM1

This is a composite material consisting of three layers: a bronze backing strip and a sintered interlock matrix, impregnated and overlaid with a PTFE / lead mixture. The material shall conform to the characteristics listed in table below. In addition, the condition of the material and its surface finish shall be checked visually. |

|

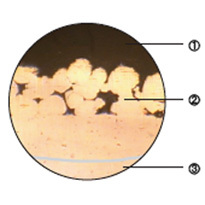

Structures

1. PTFE/fibre mixture thickness 0.01~0.03mm, provides an excellent initial transfer film, which effectively coats the mating surfaces of the bearing assembly, forming an oxide type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides max. thermal conductivity away from the bearing surface, also serves as a reservoir for the PTFE/Fibre mixture.

3. Bronze backing, provides exceptionally high load carrying capacity, excellent heat dissipation and very good corrosion resistance.

|

|

Typical Applications

This material meets the demanding criteria for long life and trouble-free performance with or without lubricant, of high safety factor even.

The bronze backing provides a high corrosion resistance, anti magnetic properties and a good thermal conductivity, The bearings are particularly appropriate for high temperature environment where no oil is efficient and the machine must be under successive long period working condition.

The typical applications covered Steel metallurgy industry such as bushes for roller grooves of successive casting machines, cement grouting pumps and screw conveyers for cement and so on.

Technical Data

|

Physical and Mechanical Properties

|

Usage

|

|

Thermal Conductivity λ

|

60

|

W/mK

|

dry

|

very good

|

|

Maximum Operating Temperature Tmax

|

280

|

°C

|

oil lubricated

|

good

|

|

Minimum Operating Temperature Tmin

|

-200

|

°C

|

grease lubricated

|

fair

|

|

Compressive Yield Strength σc

|

300

|

N/mm2

|

water lubricated

|

good

|

|

Maximum Static Load Psta,max

|

140

|

N/mm2

|

process fluid lubricated

|

fair

|

|

Maximum Dynamic Load Pdyn,max

|

140

|

N/mm2

|

|

|

Maximum Sliding Speed V-dry

|

2.5

|

m/s

|

|

Maximum PV Factor-dry, continuous operation

|

1.8

|

N/mm2 * m/s

|

|

Maximum PV Factor-dry, intermittent operation

|

3.5

|

N/mm2 * m/s

|

|

Coefficient of friction f-dry

|

0.02-0.25

|

|

|

|

Coefficient of friction f-oil lubricated

|

0.02-0.12

|

|

|

Other Standard CM1 Composite Mateiral Parts

|

| Display of CM1 Composite Plates & Strips |

|

|

| CM1 Composite Plates & Strips |

CM1 Composite Plates & Strips |

|

| Inspection & Measurement of CM1 Composite Plates & Strips |

|

|

| CM1 Composite Plates & Strips |

CM1 Composite Plates & Strips |

|

| Packaging of CM1 Composite Plates & Strips |

|

| Packaging of CM1 Composite Plates & Strips |

|

| Wooden Case Packaging of CM1 Composite Plates & Strips |

|

| Specifications of 5.3.1 Composite material CM1 - SinoBronze Co., Ltd. |

|

S07190DUB S10190DUB S15240DUB S20240DUB S25240DUB S30240DUB